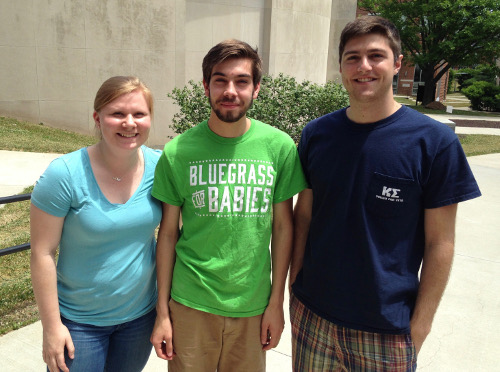

Denison Seminars encourage faculty and students to collaborate and make connections across different ways of thinking within or between disciplines. The seminar was taught by Lew Ludwig, professor of mathematics and Christian Faur, director of collaborative technologies for the fine arts at Denison.

Student learning was facilitated by their ability to carry the design process from initial abstract idea to concrete printed items that were both aesthetic and useful. (See 3dprintingdenison.wordpress.

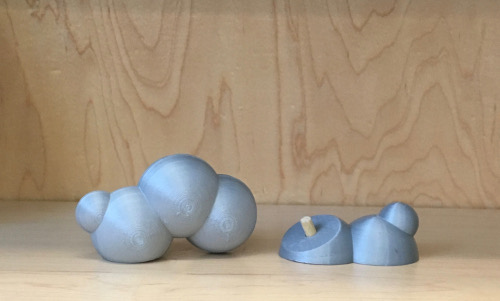

Linnea Wethekam designed and printed a prototype for a model that will be used in the Intermediate Biochemistry class to show the angles between atoms in peptides that make up proteins. She designed her model to portray the actual space that each atom requires at scale to show how the arrangement and bulk of atoms influence the angles between atoms in different peptide molecules. Wethekam reflects on her project by explaining that she “wanted to print something that would benefit the department and allow for an understanding of a concept that requires a physical example.” She also explains that the most challenging part of the project was finding the right scale so that all parts of the model would be to scale.

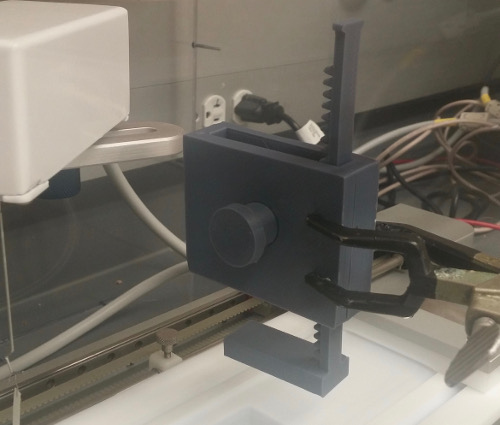

Jarrett Dillenburger has done summer and semester research on a collaborative project between the Reczek and Edwards labs to create thin films of molecules relevant in organic electronics. One method to create ordered films is to transfer films created at the surface of the liquid water to a solid support such as a silicon wafer. While this transfer process is customarily done with a commercial mechanism, Dillenburger designed and printed a simplified device to transfer floating layers to solid surfaces. The iterative design process emphasized in the course taught him how to mesh simplicity with effective function. Dillenburger’s prototype device was put to work this summer and showed the feasibility of using this transfer method to create interesting thin films of the naphthalene diimide molecules synthesized in the Reczek lab.

Jack Sundberg tied his chemistry research experiences in the Fantini lab to his final project. He designed and printed a prototype for a specialized clamp that is used to hold together the glassware he uses in the lab to run reactions. This summer while the reactions are running in the lab, Sundberg continues to modify his design and print out clamps made from a plastic resistant to the solvents he uses in his reactions. When asked about his project Sundberg explains “This project really ties together the core essentials of the Denison education by bringing together seemingly unrelated subjects, and I was able to apply 3D-printing to chemistry in a practical, handy way. Having a scientist's perspective on things allowed for this jump in application from one subject field to another.”